1000D Delta Parallel Robot-60/120 Times/Min, Up 12KG,Large Travel

Overview

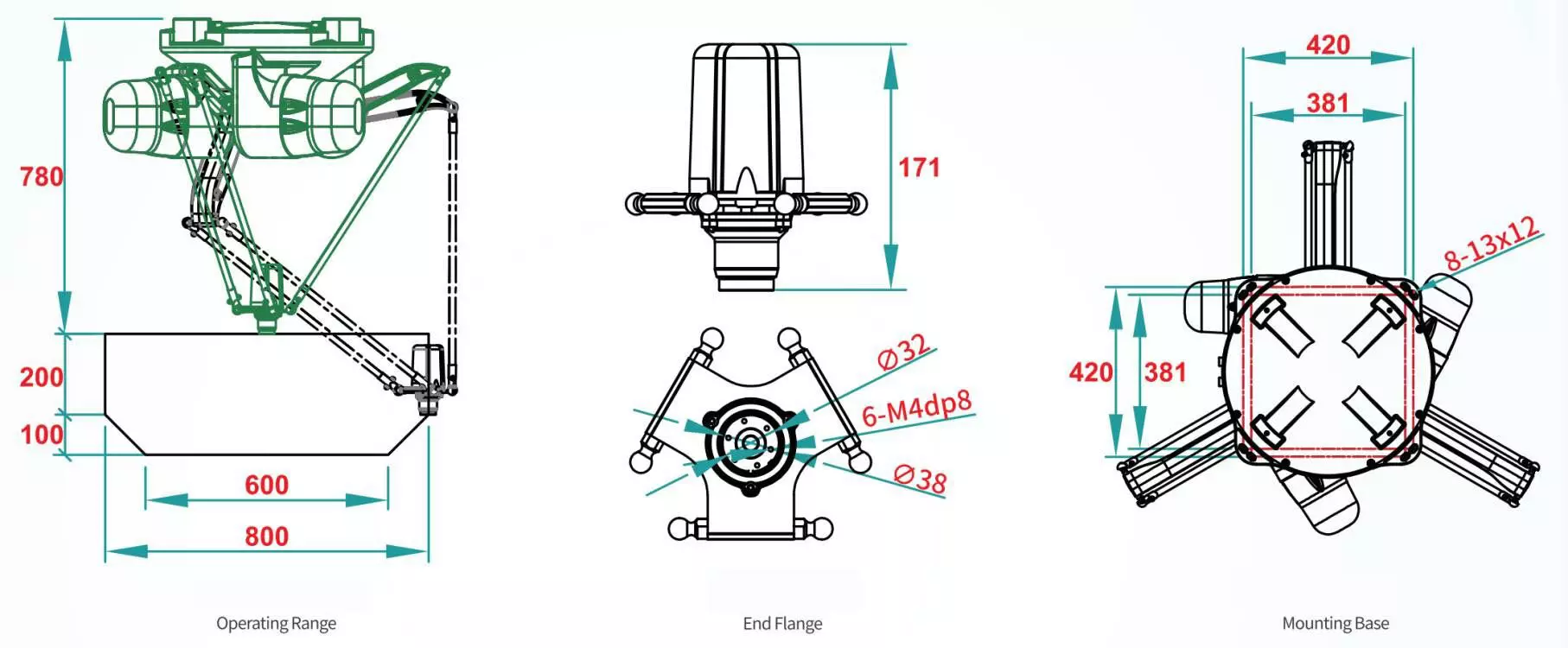

The Delta Parallel Robot is a cutting-edge automation solution designed for high-speed precision tasks in various industrial environments. Capable of performing up to 120 cycles per minute and handling payloads of up to 12KG, this robot is ideal for tasks requiring both speed and accuracy. Its large travel range allows for greater flexibility in applications, making it a versatile tool for industries that demand rapid and reliable robotic assistance.

Engineered with advanced parallel kinematics, this Delta robot is optimized for fast and efficient pick-and-place operations, packaging, and assembly processes. Its robust design ensures stable performance even at high speeds, while its precision control allows for the meticulous handling of delicate components.

| Configuration | |

| Settings | Brand |

| Servo Motor | Warsonco/Panasonic |

| Machine Reducer | Nidec corporation/green |

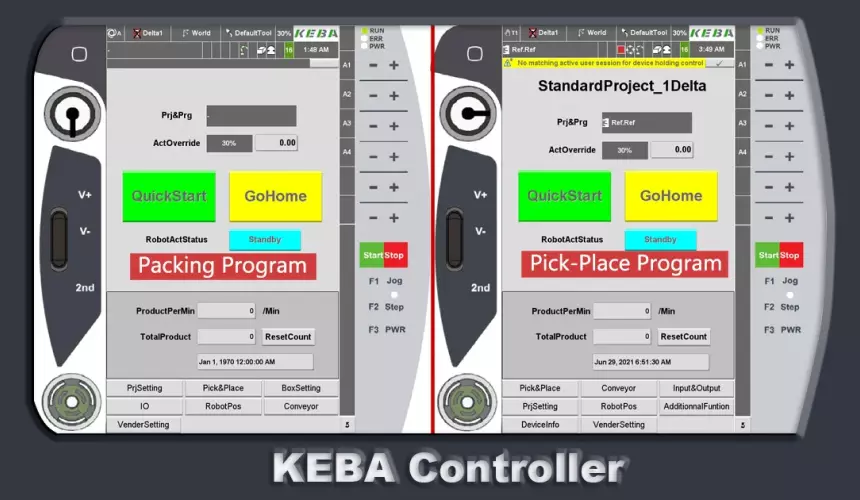

| Controller | Austria KEBA |

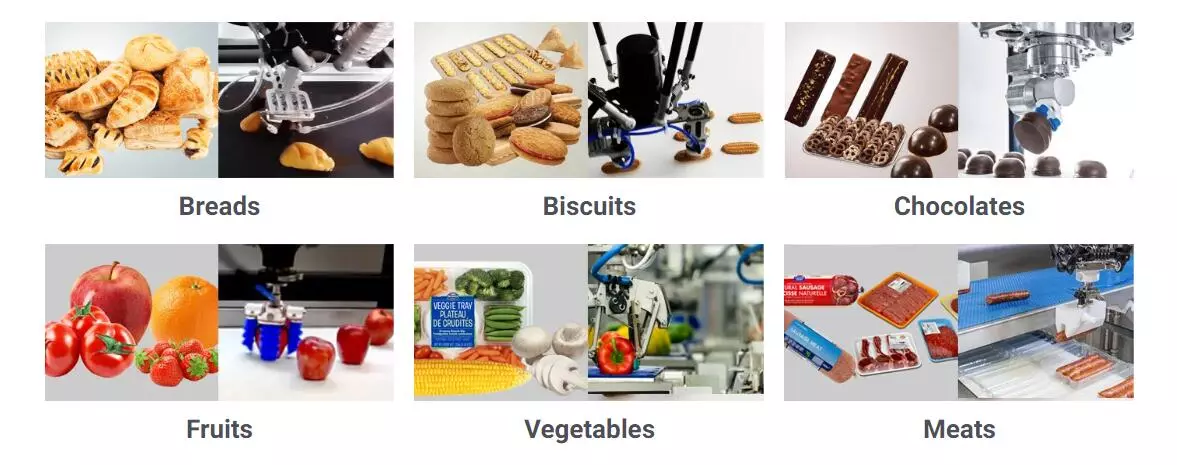

Applications

The Delta Parallel Robot is versatile and can be deployed across a wide range of industries for various applications:

✔ Packaging: Ideal for high-speed sorting, packing, and palletizing of products, ensuring efficiency in packaging lines.

✔ Pick-and-Place Operations: Perfect for precise pick-and-place tasks, such as handling small components in electronics manufacturing or food items in the food processing industry.

✔ Assembly: Suitable for assembling parts in automotive, electronics, and consumer goods manufacturing, enhancing accuracy and reducing assembly times.

✔ Pharmaceuticals: Ensures the safe and precise handling of delicate pharmaceutical products, maintaining product integrity and compliance with industry standards.

✔ Food and Beverage: Provides fast and accurate sorting and packaging of food items, ensuring consistent quality and reducing the risk of contamination.

We've pre-installed the application in the robot, you can use the robot directly without any code.While you can program your applicant with Keba demonstrator easily.

Features:

● Cost Effective

● Easy to Operate

● Modular System

● Low Maintenance

● Certificate:lS0,CE

● Application:Food, Beverage, Pharmaceutical, Consumer Electronics

● Warranty:1 Year, Free Lifelong Technical Support

● Communication protocols, Modbus TCP/P, EtherCAT, CAN, RS232/485