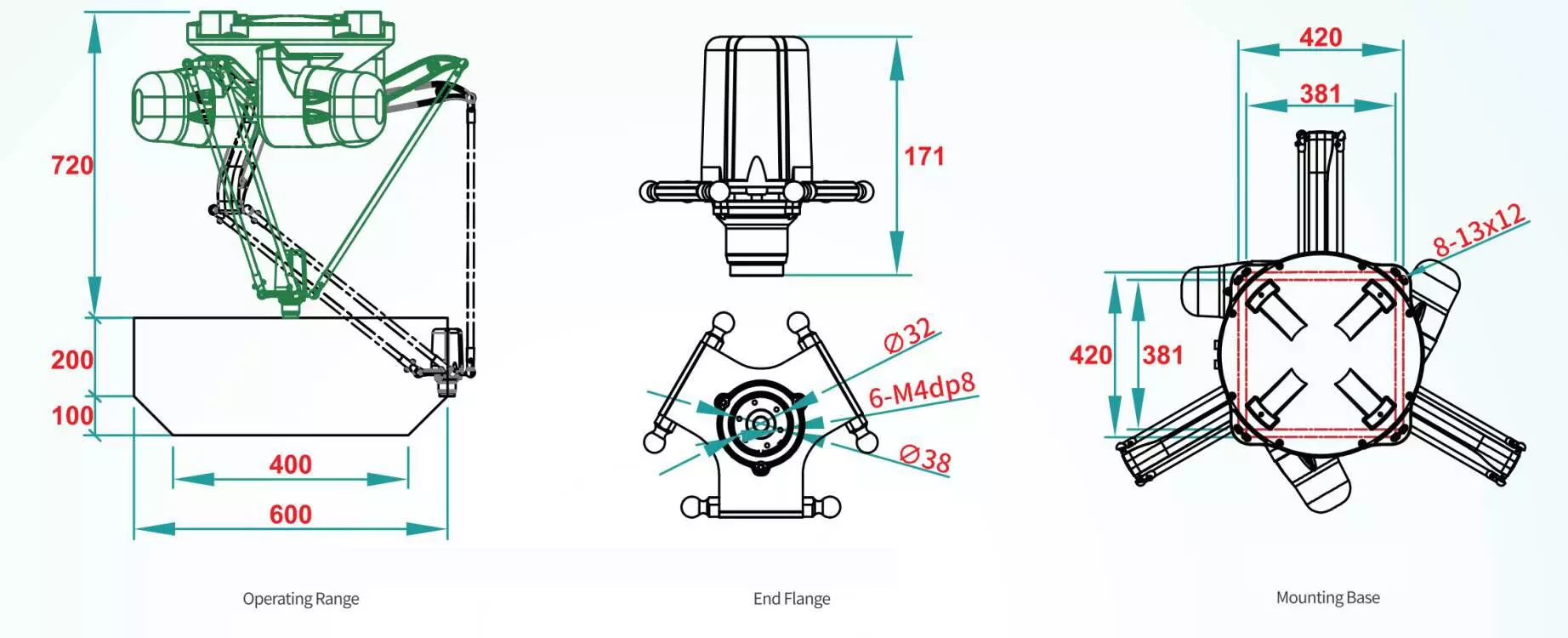

600D Delta Robotics - 60-120 Times/Min, Up to 12KG,Large Travel, High-Speed Sorting & Packing

Overview

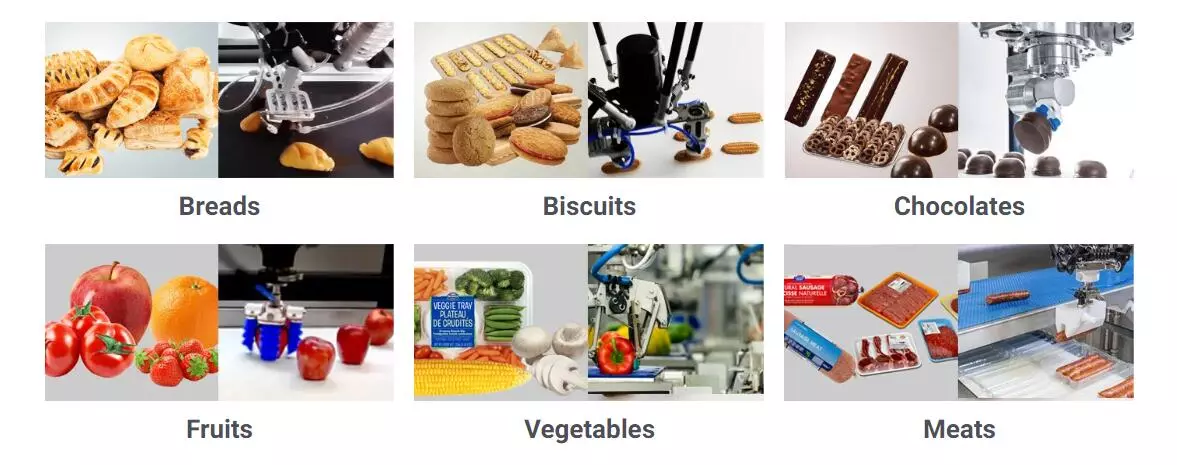

Delta Robotics unveils a fast and accurate Pick & Place robot with enhanced features developed to innovate the way production is done. With the speed of operation ranging between 60 to 120 cycles per minute and supporting a travel distance of 600mm, this robot is fitted to do sorting and packing jobs with high velocity and precision. Featuring a triangular body and a state-of-the-art motion control system, Delta Robotics provides an effective answer to industries in need of boosting manufacturing performance for the smart manufacturing era.

The Zhihua series parallel robot embodied in Delta Robotics’ portfolio includes a unique setup of XYZ linear motions and rotational motions around the Z-axis. This design makes the tool ideal for high-speed application, inexpensive, and easy to use hence suitable for several industrial uses.

| Configuration | |

| Settings | Brand |

| Servo Motor | Warsonco/Panasonic |

| Machine Reducer | Nidec corporation/green |

| Controller | Austria KEBA |

Features

✔ Unique Spring Design: Includes a small spring device that serves not only as an additional mechanism to increase the robot’s service life but also increases operational safety.

✔ High Rotation Accuracy: The fourth axis of the robot secures remarkable rotational stability with the accuracy of 0. 05 degrees of freedom which in turn makes it possible to achieve very delicate and fine motion as it is required in ✔ various high accuracy operations.

✔ Inverted Installation Capability: However, the robot can also be mounted in an inverted fashion, with excellent tracking characteristics offered and the system is fully adaptable for different production arrangements.

✔ Cost-Effective Solution: Able to deliver a high performance at the relatively low price point with a visual dynamic tracking, to improve the business processes and minimize the overall time loss.

✔ Strong Performance: The robot has great bearing capacity; it is very rigid with better dynamic characteristics. This makes it capable of carrying heavy loads while perform at optimum level or at the highest level possible.

✔ Lightweight Design: Reduced self-weight load ratios make it easier for the robot to handle the products without putting excessive stress on them thus enhancing the robot’s durability.

Previous: WSC 800D 4 Axis Delta Robot--60/120 Times/Min, Up 12KG,Large Travel

Next: No More